Fill material

Fibers are available in a variety of colors, shapes and sizes. Depending on your application, working conditions and desired brushing effect, we select the type of material, its specific properties (antistatic, wax coating, etc.), as well as the color, shape and length of the fibers.

Resistance

The environment in which the brush is used is crucial to the choice of fibers. It is important to consider factors such as resistance to temperature, acids, alkalis, chemicals and humidity, as well as brush resilience, speed and pressure.

Food safety

The fibers KOTI-TRIBOLLET uses for food contact comply with European food safety regulations and requirements. A safe production process protects both consumer health and your brand’s reputation.

Durability

At KOTI-TRIBOLLET, we practice innovative recycling. During the production process, we cut the bristles to the desired length for each customer application. Remaining waste, such as small cut pieces, is reused to manufacture short-bristle brushes, giving them a new lease of life.

| Fiber type | Benefits |

| Nylon 6.6 | Mainly used in industrial applications, this material offers excellent resistance to heat and wear. |

| Nylon 6.12 | More robust than Nylon 6.6, this material does not retain moisture |

| Rilsan | Extremely wear-resistant and moisture-proof |

| Polypropylene (PP) | This material is acid-resistant and does not absorb moisture. However, its wear resistance is lower than that of Nylon 6.6 and Nylon 6.12. |

| Polyester (PBT) | This material offers excellent resistance to heat and wear, does not retain moisture and is certified for food use. |

| Nylon abrasive | Perfect for removing delicate burrs and obtaining a satin finish. |

| Polyethylene | This material offers good chemical resistance and maintains superior rigidity when wet, compared with nylon. |

| Fiber type | Benefits |

| Metal trim | Steel (high-strength steel, brass steel, stainless steel, hardened steel), as well as brass and bronze. |

| Steel | To remove carbon and burrs, a highly aggressive packing is used |

| Brass | Polished and satin-finished, with excellent explosion-proof electrical conductivity, slightly lower than that of bronze. |

| Stainless steel | Polished and satin-finished with excellent antistatic electrical conductivity, suitable for humid environments. |

| Brass-plated steel | Excellent tensile strength, long service life and efficient deburring |

| Brass-plated steel wire | Exceptional deburring and long service life. |

| Phosphor bronze | High electrical conductivity, surface treatment of wood and metals, and spark-free machining |

| Fiber type | Benefits |

| Horsehair | Flexible for gentle cleaning (ideal for plastic surfaces such as belts). |

| Goat's hair | Flexible for gentle cleaning (ideal for plastic surfaces such as belts). |

| Pork silk | Stiffer than horsehair. |

| Quill pen | Gives wooden furniture a patina finish after polishing |

| Ostrich feather | Extremely flexible material, mainly used for dusting and polishing bodywork. |

| Tampico | Stiffer than hog bristles, ideal for metal with polish. |

| Fiber type | Benefits |

| WYTEX conductive nylon | Synthetic fiber with high electrical conductivity |

| Nylon HT | Heat-resistant up to 150°C |

| Pekalon | Synthetic fiber with high heat resistance (up to 180-200°C). |

| PEEK | Synthetic fiber with exceptional heat resistance (up to 250°C). |

| Optical fiber | Exceptional heat resistance, high elasticity and excellent impact strength (also used in the paper industry). |

| Carbon | Exceptional electrical conductivity, extremely fragile material. |

| FRH | Self-extinguishing nylon fiber, with no toxic gas emissions in the presence of flames, used in areas where safety is paramount (public transport). |

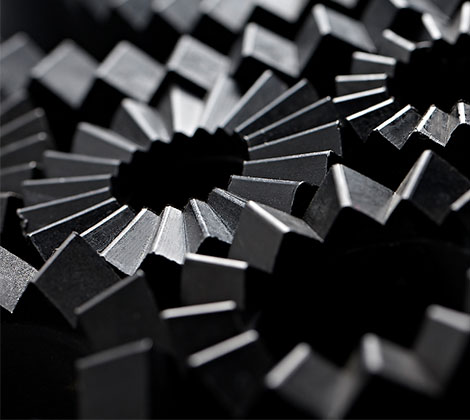

core materials

We also define the properties of the substrate to suit your application and the desired result, such as material type, color, shape and strength. With our wide range of materials, we can meet your needs even better.

Customized core molds

The material and shape of the materials used determine your application. In our development and test environment, we design and test brushes with specific shapes. We create these specific shapes using 3D printers and custom molds. So we know how to design and produce a brush that meets your needs.

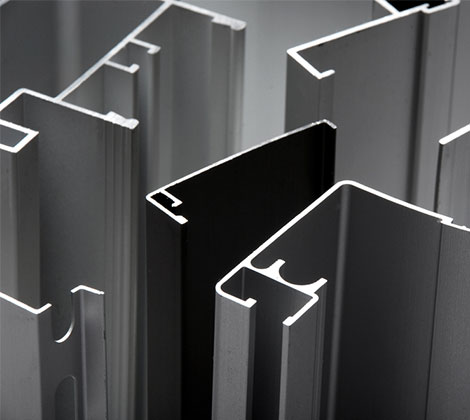

Extrusion profiles

We provide support for the development of extrusion profiles and help you to tailor your profile perfectly to your requirements. When designing the profile, we take into account the joining method and your application. Contact our technical advisors for more information.

Your success is our success

Ready to optimize

your processes?

At KOTI-TRIBOLLET, anything is possible. Wondering what options are available for your application? We’re here to help.