towards a

sustainable future

At KOTI, we believe in continuous improvement. We take responsibility for our production processes and strive to reduce our environmental impact. As a family-run business, we’re very conscious of the legacy we want to leave to future generations.

Recycling materials

Recycling materials is a key element of our sustainability policy. Since 2012, we have been shredding a portion of residual materials, including returned brushes and production leftovers. These materials are then reused to manufacture new parts. Surplus materials are also used in areas other than brush production.

Reducing emissions

KOTI strives to minimize its impact on the environment and is committed to reducing its emissions. We invest in energy-efficient production methods and are constantly looking for ways to reduce our energy consumption. Our truck will soon be running on renewable biofuel, and all the vehicles we deploy are hybrid or electric.

Reusing brushes

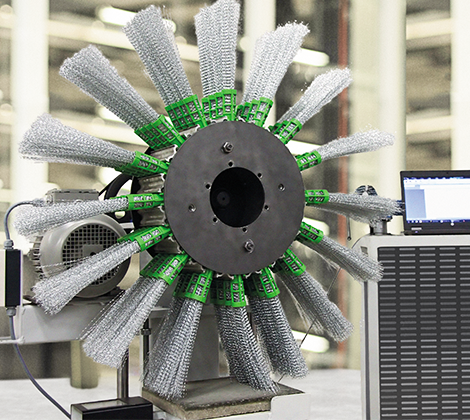

Brushes can be reused by replacing worn fibers.

This method offers economic and environmental benefits by reducing material waste and costs.

Wear limit

When the fibers of your KOTI brush reach their wear limit, you can return the worn brush to KOTI.

Checking

We ensure that the shaft structure is free of defects, check tolerances and bearings, and remove the old lining.

Refurbishing

Once approved, the brush is reused. We remove the old bristles and replace them with new ones, a process carried out in our specialized factory.

A brush like new

You’ll receive the same brush core with new fill materials. This way, we reduce our ecological footprint together.

Research & Development

KOTI has its own brush development and testing department. The design, testing, planning, execution and verification cycle aims to improve environmental performance and avoid wasting raw materials and energy. Our team is constantly working to identify new methods and materials to make our products even more sustainable. We collaborate with industry experts and participate in initiatives aimed at reducing the environmental impact of industries.

Better results

less costs

Since 2010, all KOTI sweeping brushes have been equipped with a patented wear indicator. This active control mechanism increases brush life by 8-15%. Each time we deliver a brush, we check it for wear. What’s more, we offer free ongoing training for drivers every year, if required. This course provides drivers with the tools they need to optimize their machine settings, ensuring better sweeping results and longer brush life.

Your success is our success

Optimize your application ?

Ready to take your business to the next level? Our specialized consultants are here to help.