Customer-specific brushing solutions for all industries

INDUSTRIAL BRUSH

KOTI-TRIBOLLET, founded in 1911, is a leading family-owned company in brush technology specialised in the production of industrial brushes. For over 100 years we are more than just a supplier, we have been developing and producing industrial brushes for a wide variety of applications and industries for our customers worldwide.

In countless processes, brushes often play an inconspicuous but essential role. They can be found almost anywhere where products or materials need to be handled. Technical brushes are versatile and offer a flexible solution for a growing number of – often complex – industrial processes. An important advantage of using brushes is the favourable price-performance ratio.

Whether it’s sealing conveyor belts with brush strips, surface treatments in the metal or wood industry using spiral or punched brushes, or cleaning products in the food processing industry – we provide tailored brush solutions for a wide range of applications. By combining high-quality materials with our extensive knowledge and expertise, we ensure maximum efficiency and quality for our customers.

Would you like to find out what industrial brushes can do for your project?

Contact us today or explore our wide range of technical products.

Reliable protection, sealing and guidance | INDUSTRIAL BRUSHES

STRIPS AND SEALING BRUSHES

Our strip and sealing brushes provide a flexible, adaptable, and durable solution for a wide range of applications. Designed for precision and efficiency, they offer optimal sealing, protection, and guidance across various industries.

With multiple configurations available—from standard designs to flexible and fully customized solutions—you can tailor the brush strips to perfectly fit your specific needs. This ensures maximum durability, reduced maintenance, and improved performance, even in demanding environments.

High-performance solutions for demanding applications | INDUSTRIAL BRUSH

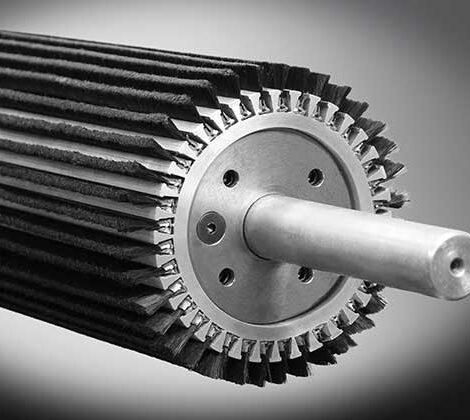

SPIRAL BRUSHES

Our spiral brushes provide a powerful and versatile solution for technically complex and heavy-duty applications. With high bristle density and extensive configuration options, you can fully customize the brush to meet your specific requirements, ensuring optimal performance and maximum efficiency.

These brushes are highly suitable for high rotational speeds, maintaining durability and reliability even under extreme conditions. This translates to less wear, a longer lifespan, and lower maintenance costs, keeping your production process running smoothly and cost-effectively.

Versatile, high-performance solutions for all sectors | INDUSTRIAL BRUSH

ROLLER BRUSHES

Our cylindrical brushes offer maximum versatility thanks to a wide choice of materials, drilling patterns and density options. This means you can perfectly customize the brush for your specific application, guaranteeing optimum performance and efficiency.

Whether you’re in the metal, wood, glass, or food industry, our brush rollers provide precision, durability, and consistent processing of your products. With high-quality materials and customized solutions, you benefit from reduced wear, lower maintenance costs, and an extended lifespan for your system.

Cost-effective and long-lasting brush solutions | INDUSTRIAL BRUSH

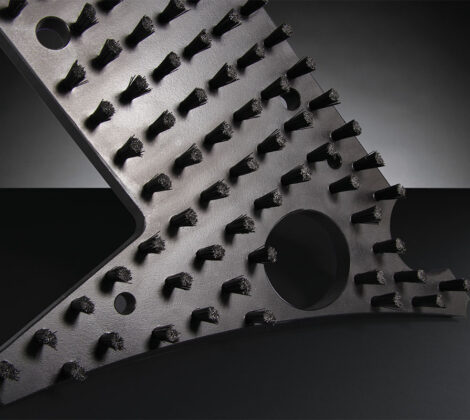

CYLINDRICAL BELT BRUSHES

Our strip brush rollers provide a durable and cost-effective solution for your brush systems. With a one-time investment in the core, you can easily and quickly replace the brush strips as they wear out. This reduces long-term costs and minimizes downtime in your production process.

Additionally, the robust construction ensures reliable performance, even in challenging conditions. This means less maintenance, fewer disruptions, and maximum efficiency for your production environment.

Fast, efficient and flexible | INDUSTRIAL BRUSH

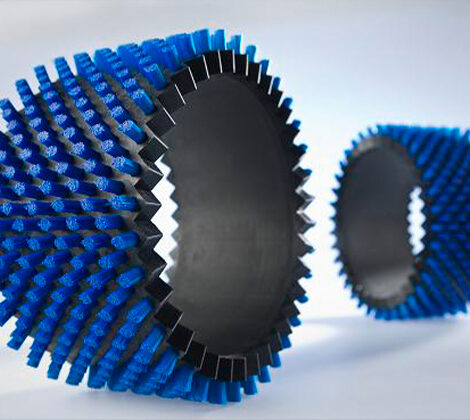

QUICKSNAP BRUSH SEGMENTS

Our QuickSnap brush segment system provides a smart and modular solution for your brush systems. With its patented interlocking design, the brush segments seamlessly connect, creating a smooth and consistent brush surface for optimal performance.

With the QuickSnap system, you can easily assemble your own customized brush roller, tailored to your specific application. Worn-out brush segments can be quickly replaced without the need for complex tools, reducing downtime, lowering maintenance costs, and maximizing efficiency in your production process.

Prevent disruptions and protect your products | INDUSTRIAL BRUSH

ANTISTATIC BRUSHES

Nos brosses antistatiques réduisent efficacement l’accumulation d’électricité statique lors du traitement des matériaux. Elles évitent ainsi les perturbations, l’adhérence des matériaux et les décharges indésirables, garantissant un processus de production plus sûr et plus efficace.

Designed to protect sensitive and delicate surfaces without damage, they are ideal for use in electronics, packaging, textile, and plastics industries. By controlling static charges, you prevent production delays, defects, and downtime, resulting in higher product quality and lower costs.

Efficient and reliable solutions for transport and cleaning | INDUSTRIAL BRUSH

BRUSH BELTS

Our brush belts provide a durable and efficient solution for transporting, guiding, cleaning, and surface treatment across various industries. Their flexible and robust construction ensures consistent and even material processing without causing damage.

By combining high-quality materials with customizable options, our brush belts can be tailored to your specific application needs, from dust and debris removal to controlled material transport. This leads to reduced wear, lower maintenance costs, and a longer lifespan, making your production process more efficient and reliable.

Flexible and durable solution for optimum support and cleaning | BROSSE INDUSTRIELLE

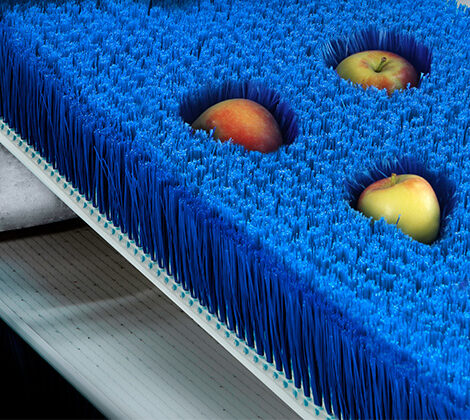

BRUSH PLATES

Our brush plates provide a versatile and efficient solution for supporting, guiding, transporting, and cleaning delicate or fragile materials. With high-quality and durable bristles, they ensure gentle, even, and controlled processing, preventing damage and excessive wear.

Brush plates are ideal for applications in the glass, wood, metal, and food industries, where precision and product protection are essential. Their modular design allows for easy customization to meet your specific needs, resulting in reduced downtime, lower maintenance costs, and a more efficient production process.

High-Performance solutions for demanding applications | INDUSTRIAL BRUSH

BRUSHES FOR POWER TOOLS

Our power tool brushes are designed for thorough cleaning, deburring, polishing, and surface finishing in demanding industrial applications. With high-quality bristles and a durable construction, they deliver maximum performance and longevity, even under heavy use.

Available in a wide range of sizes, materials, and configurations, our power brushes can be fully customized to meet your specific needs—whether for metalworking, woodworking, plastics processing, or the automotive industry. This results in faster processing, consistent quality, and lower maintenance costs, making your production process more efficient and cost-effective