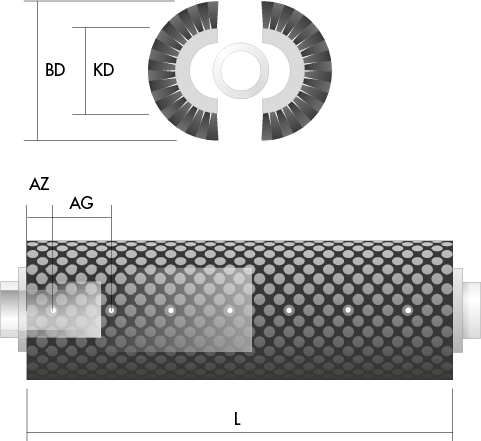

Split core brush

Split core brushes are a removable version of the implanted rollers. It’s a brush constructed from two brush elements. This system can be used where brushes need to be changed frequently and brush axles are difficult to dismantle. The great advantage of this system is that the brush axle can remain in the machine, so that brushes in 2 half-shells can be assembled on the axle. This saves you a lot of time and ensures that your machine has little downtime. Brushes in 2 half-shells can be assembled on the axle using stainless steel screws.

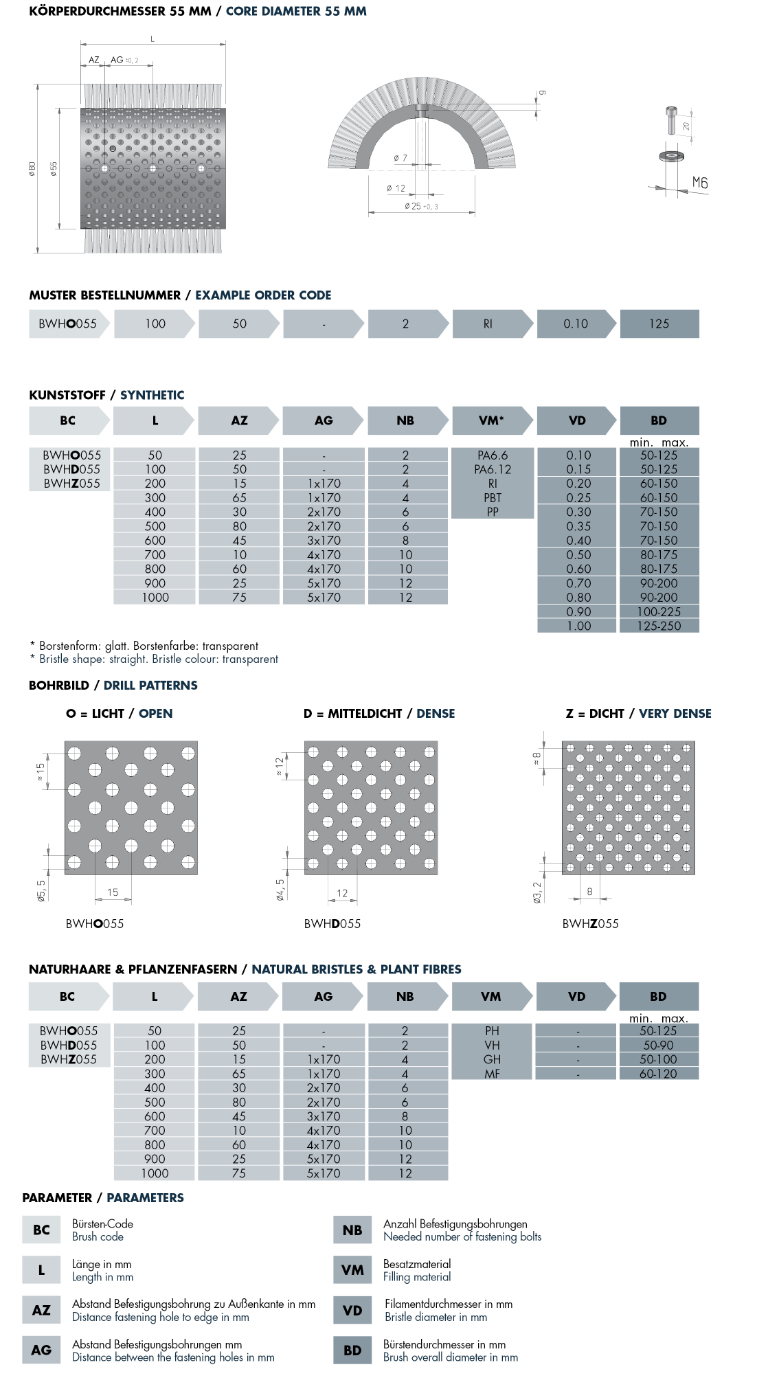

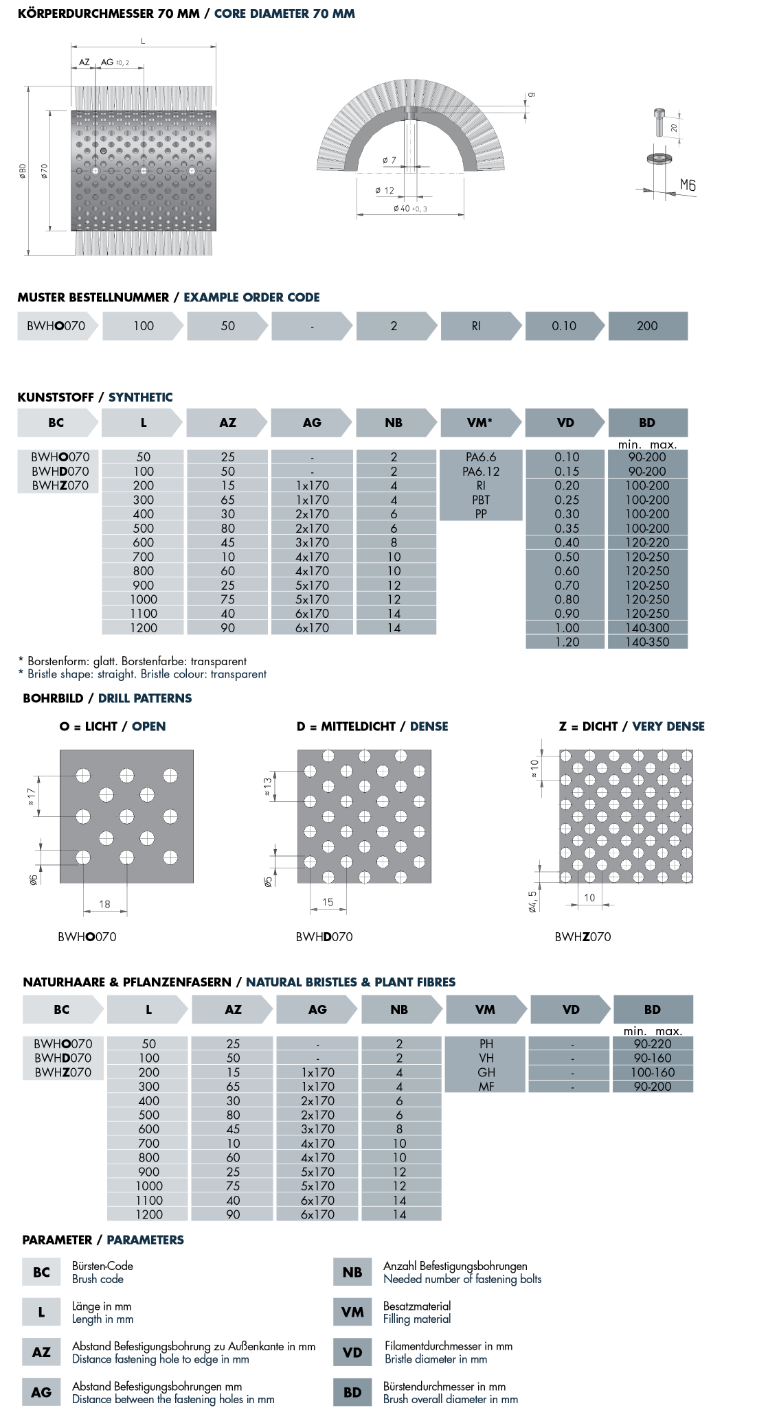

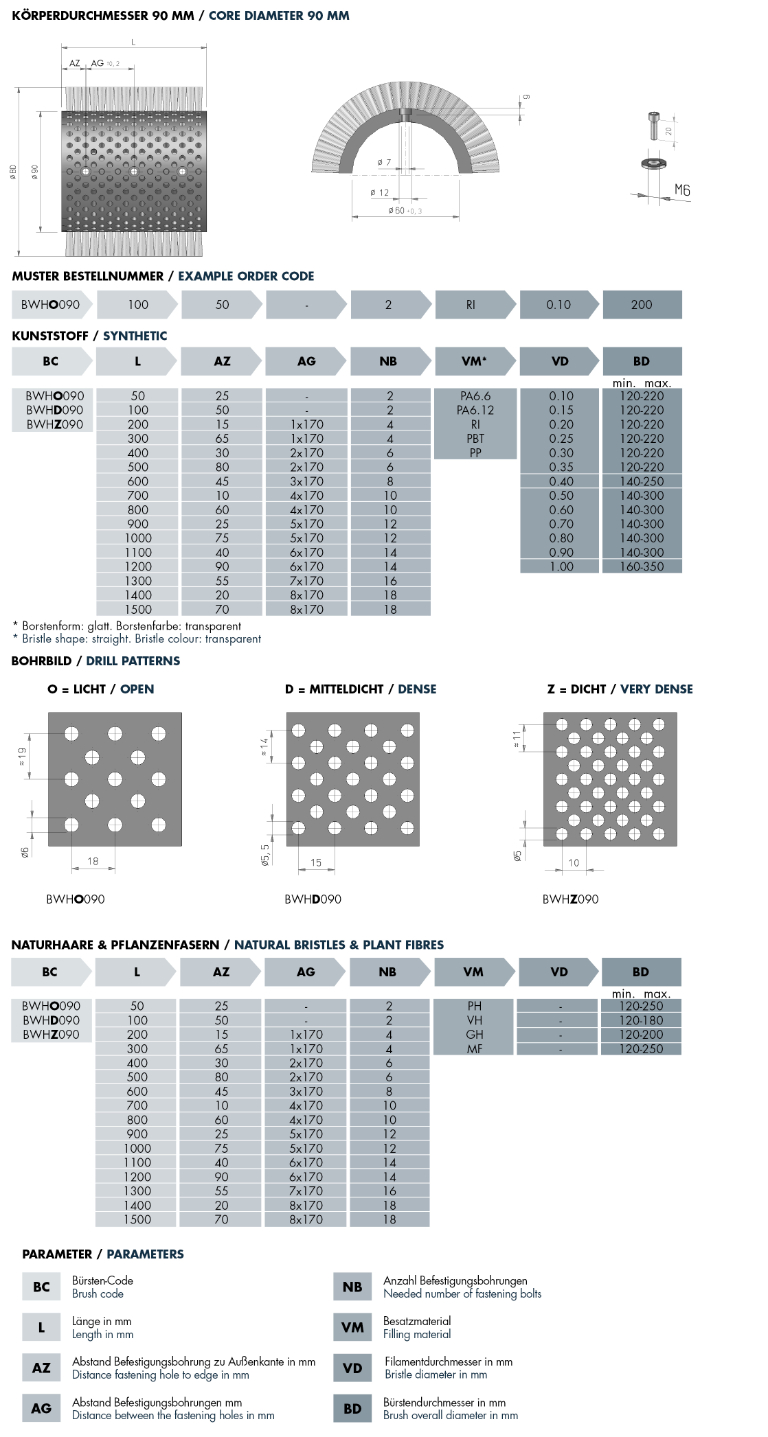

Models

The models shown are standard. For all other requests, please contact our sales department.

Parameters

- KD – Body diameter

- L – Length

- AZ – Distance of mounting hole from side

- AG – Distance between mounting holes

- NB – Number of fasteners

- VM – Lining

- VD – Fiber diameter

- BD – Total brush diameter

Lining

The type of lining we use will depend on your application and industry. Do you have any questions about which fiber to use? Please do not hesitate to contact us.

| Body material | |||

| Abbreviation | Description | Benefits | |

| PA 6.6 | Polyamide 6.6 | Suitable for industrial applications, heat and abrasion resistant | |

| PA 6.12 | Polyamide 6.12 | Does not retain moisture, better resilience than nylon 6.6 | |

| RI | Rilsan | Does not retain moisture, very high wear resistance | |

| PBT | Polyester | Heat- and wear-resistant, non-retaining and certified for food use | |

| PP | Polypropylene | Non-moisture-holding, acid-resistant, lower abrasion resistance than nylon 6.6 and 6.12 | |

| PH | Horsehair | Flexible fiber for light (e.g. for plastic strips) | |

| VH | Pork silk | Harder than horsehair | |

| GH | Goat's hair | Extremely soft fiber for delicate work | |

| MF | Tampico fiber | Harder than hog silk (suitable for metal, for example, with the addition of a polishing paste) | |

Your success is our success

Need help finding

the perfect brush?

Do you have any questions about the 2-shell brush or are you looking for a customized solution? Contact us, and we’ll be delighted to help you.

Brush in 2 half-shells

Please enter your requirements and contact details below. We’ll be happy to advise you on the best brushing solution for your needs.