ADVANCED BRUSHING TECHNIQUES

an optimized production project

In the woodworking industry, cleaning and sanding are crucial steps. Brushes are indispensable tools for maintaining and finishing wood surfaces. They remove dust, glue residues and other products, guaranteeing a smooth, even finish.

What’s more, brushes improve the efficiency of production processes by reducing manual labor and increasing precision. Whether preparing wood for varnishing or applying oils, brushes contribute to the quality and durability of finished products.

For all types of wood

KOTI-TRIBOLLET brushes are designed to treat a wide variety of wood species, from softwoods to hardwoods, as well as reconstituted wood products. This guarantees consistent, high-quality results on different materials and surface requirements.

Efficient and high-performance

Thanks to decades of expertise, KOTI-TRIBOLLET offers brushing solutions combining efficiency and precision for virtually all woodworking applications. Each brush is designed to deliver optimum results while reducing processing time and wear.

Reliable in all conditions

KOTI-TRIBOLLET brushes operate reliably in a wide range of environmental and processing conditions. Whether operating in dry or damp conditions, or at high or low temperatures, their performance and durability remain constant.

High-speed capability

The brushes are designed to operate smoothly at both low and high speeds, without compromising performance. This flexibility means they can be seamlessly integrated into different processes and machine configurations.

Durable

High-quality lining materials and robust construction guarantee long service life for KOTI-TRIBOLLET brushes. The result is less downtime, lower replacement costs and a more sustainable production process.

Adapts to all machines

KOTI-TRIBOLLET brushes are compatible with a wide range of woodworking machines, from industrial production lines to specialized equipment. Their bespoke design ensures perfect alignment with machine specifications and process requirements. Our brushes are also suitable for power tools.

Commonly used brushes

for woodworking

In the wood industry, a wide variety of brushes are used. Because we focus on your specific application, we can create a custom-made brush that fits perfectly. Below are some examples of brushes commonly used in the wood industry.

Brush laths

Our brush slats are the ideal solution for efficient transport and storage of small boards or panels. They combine intelligent design with reliable protection, ensuring that your products move safely through every stage of the production process. Integrated brushes not only save space, but also provide excellent shock absorption and optimum support, making them ideally suited to demanding environments.

- Space-saving and durable: organized storage and long-term use

- Shock-absorbing brushes: prevent bumps and scratches

- Strong support: high carrying capacity for safe handling

- Versatile: ideal for wooden frames, panels, and cabinet assembly

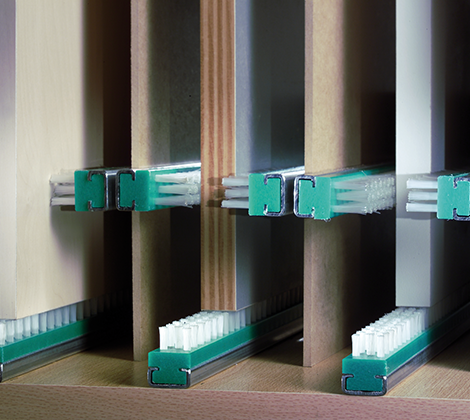

Brush strips

Our brush strips provide an effective solution for sealing holes or openings in machines or production line components. They ensure proper sealing to reduce breakdown risks and minimize maintenance costs, keeping your production running smoothly. KOTI-TRIBOLLET strip brushes offer more than just sealing:

- Efficient sealing: Prevents dust and debris entering components

- Dust extraction: Mounted on nozzle edges for optimal suction

- Improved finish: Removes dust before and after coating

- Versatile cleaning: Ideal for planks, boards, and press plates

- Customizable: Various sizes and materials available

Roller brushes for cleaning

Regular cleaning of conveyor belts is essential to prevent downtime, ensure product quality, and extend the lifespan of your belts. Our brush rollers deliver thorough and effective cleaning, keeping your production lines running smoothly. Conveyors, for example in chipboard production where wooden chips are transported via conveyor belts, can be cleaned efficiently with our brushes.

- Consistent product quality: Removes debris and dust for a clean process

- Extended belt lifespan: Prevents wear and reduces downtime

- Custom-made brushes: Tailored for guaranteed cleaning results

Roller brushes for structuring and sanding

Our roller brushes are available in abrasive versions for structuring and sanding and synthetic versions for cleaning, making them highly versatile for different woodworking applications. They deliver precision, flexibility, and improved product quality throughout the production process. Our brushes are used for:

- Preparation: Improves quality and appearance; ideal for textures and rustic effects

- Sanding: Smooths beams and boards; polishes surfaces; removes burrs and splinters

- Dust removal: Cleans before and after coating; removes debris from planks and press plates

Custom solutions

At KOTI-TRIBOLLET, we start by understanding your specific requirements. We assess your processes and challenges to provide expert advice on the right brush type, material, and design for your application. Our technical knowledge and advanced production capabilities ensure tailor-made solutions that optimize cleaning, finishing, and transport in woodworking, helping you achieve the best possible results.

Reuse the core, replace the filling, reduce waste and costs

Brush refurbishment for circular use

Your advantages

- Sustainable and cost-efficient: lower costs, less waste, reduced raw material use contributing to sustainability goals.

- Extended brush life: reuse the core, renew the filling – circular and efficient.

- Streamlined process: send us the brush, we’ll handle the rest (terms apply).

Before

The core construction of your KOTI-TRIBOLLET brush can be a valuable and costly component. When the fill material reaches its wear limit, return it to us. We inspect the core for defects, check tolerances and bearings, and if it meets our standards, remove the old fill material.

After

This process is carried out in our specialized facility. Once completed, you receive the same core with new fill material, helping us reduce our ecological footprint together. A wide range of fill materials are available: abrasive, antistatic, flame-retardant, natural fibres, synthetic materials, wire or individual material combinations.

Fill materials

We work with a wide range of abrasive materials and grit sizes to precisely tailor the surface finish to each application. Depending on the specific requirements, we use filament materials such as ANS and ANA, stainless steel wire, and brass‑coated steel wire.

For fine, uniform surface structures, abrasive polymer bristles with integrated grit provide controlled and consistent results. When a deeper texture or a more pronounced wood grain is required, robust steel wire filaments are used to enhance the natural character of the wood.

| Fill materials in the wood industry | ||||

| Type | Description | |||

| ANS | Round filament with integrated silicon carbide (SIC) grit, used worldwide. Available in grit sizes from 46 to 1000. Offers good heat stability, high chemical resistance, and uniform grit distribution. | |||

| ANA | Standard round filament with aluminium oxide (AO) grit, available in grit sizes from 46 to 1000. Provides good heat stability, high chemical resistance, and even grit distribution. | |||

| INOX | Stainless steel wire, acid‑resistant, available crimped or straight. Material grades 1.4301 / 1.4310 or 1.4401 / 1.4571. Diameter range: 0.30 mm to 1.00 mm. | |||

| LIT | Brass‑coated steel wire in cord construction. Springy and tough, crimped. Diameter range: 0.15 mm to 0.38 mm. | |||

| LTE | Brass‑coated steel single wire. Springy, crimped. Diameter range: 0.15 mm to 0.38 mm. | |||

| And many more... | A wide range of additional materials is available. The final selection is always determined in consultation, based on your specific application, requirements, and desired surface finish. | |||

your success is our success

Ready to optimize

your applications?

Our specialist advisors will be happy to help you discover what our brushes can do for your industry. Get in touch with us