Tufted roller brush

The tufted roller brush is one of our most versatile products. This brush is used in many industries for a variety of applications. Implanted cylindrical brushes are a universal solution, thanks to the many possible combinations of material, filling and density. Material, packing, drilling pattern and hole diameter depend on the application. For example, in the pharmaceutical, chemical or graphics industries, brushes will need to be resistant to chemicals, while in other industries, other characteristics will be required (such as wear resistance, flexibility, etc.).

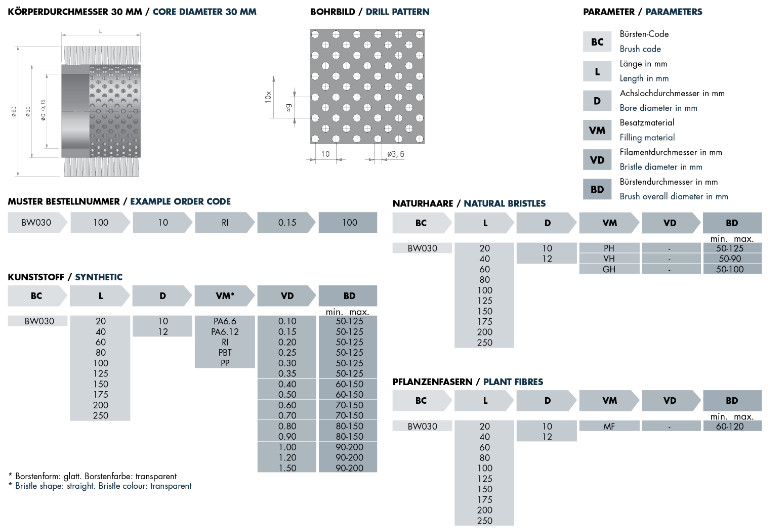

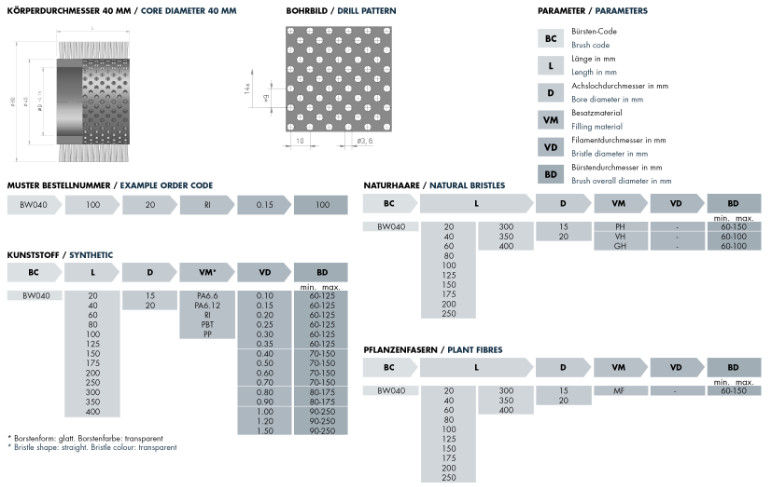

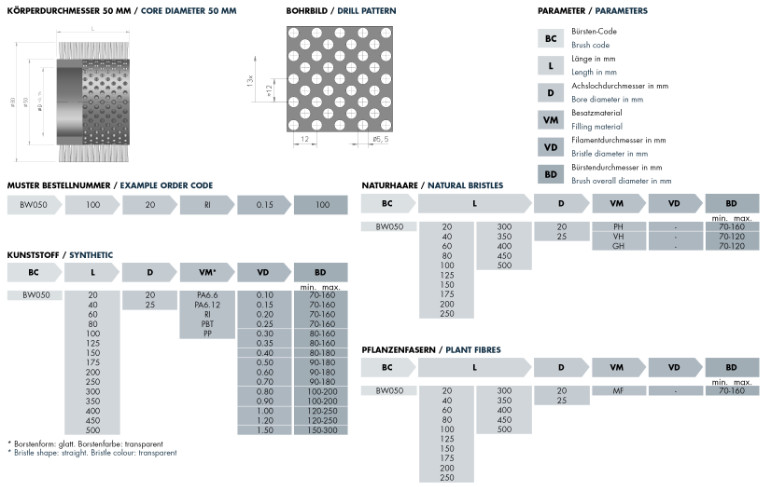

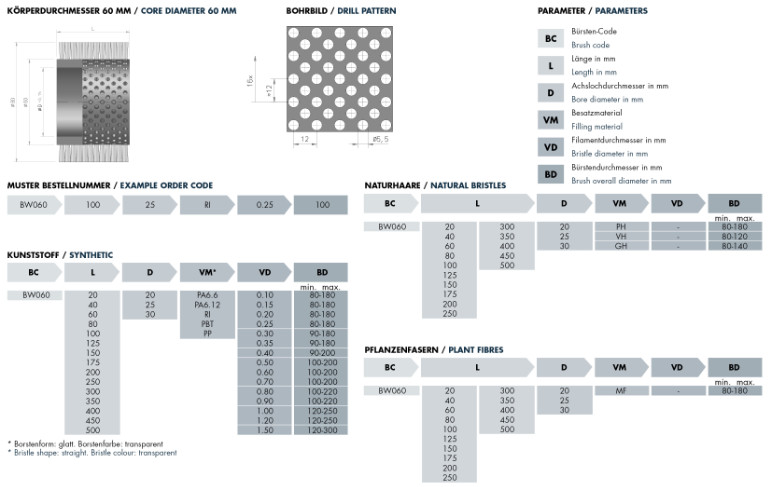

Models

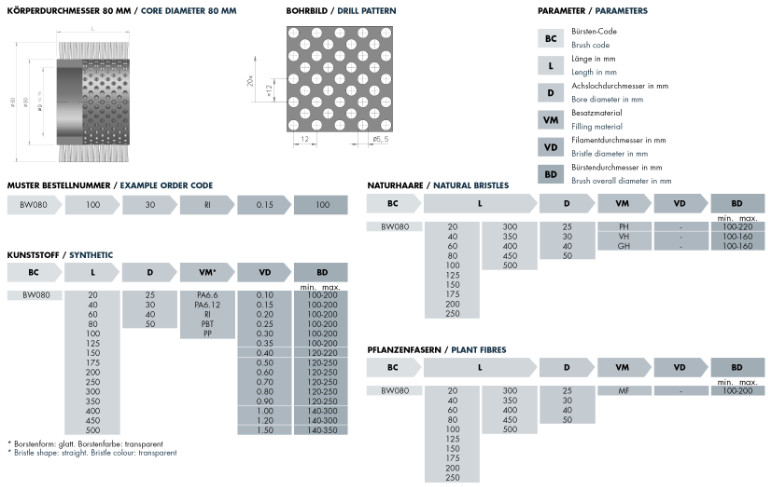

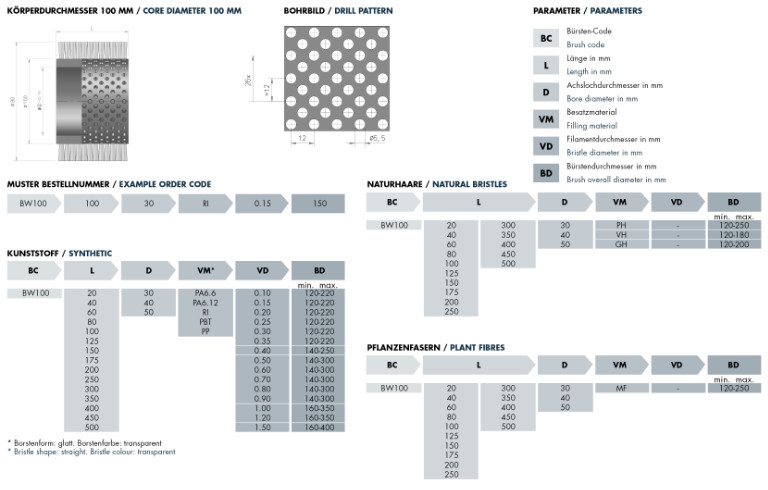

The models shown are standard. For all other requests, please contact our sales department.

Parameters

- L – Length brush

- D – Bore diameter

- KD – Body diameter

- BD – Brushing diameter

- VM – Fill material

- VD – Fiber diameter

Fill material

The type of Fill material we use will depend on your application and industry. Do you have any questions about which fiber to use? Please do not hesitate to contact us.

| Fill material | |||

| Abbreviation | Description | Benefits | |

| PA 6.6 | Polyamide 6.6 | Suitable for industrial applications, heat and abrasion resistant | |

| PA 6.12 | Polyamide 6.12 | Does not retain moisture, better resilience than nylon 6.6 | |

| RI | Rilsan | Does not retain moisture, very high wear resistance | |

| PBT | Polyester | Heat- and wear-resistant, non-retaining and certified for food use | |

| PP | Polypropylene | Non-moisture-holding, acid-resistant, lower abrasion resistance than nylon 6.6 and 6.12 | |

| PH | Horsehair | Flexible fiber for light (e.g. for plastic strips) | |

| VH | Pork hair | Harder than horsehair | |

| GH | Goat's hair | Extremely soft fiber for delicate work | |

| MF | Tampico fiber | Harder than hog silk (suitable for metal, for example, with the addition of a polishing paste) | |

Your success is our success

Let's find the ideal solution together

Do you have any questions about the tufted roller brush, or are you looking for a customized solution? Contact us, and we’ll be delighted to assist you.

Tufted roller brush

Please enter your requirements and contact details below. We’ll be happy to advise you on the best brushing solution for your needs.