Customer-specific brushing solutions for all industries

Expertise in technical brushes

for every industrial sector

KOTI Tribollet specializes in the manufacture of strip brushes, a type of technical brush used in numerous industrial applications. Thanks to our engineering expertise and flexible production capacity, we design custom strip brushes tailored to the specific requirements of each sector..

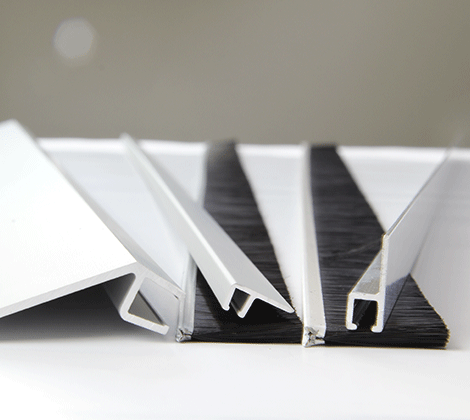

Our strip brushes are available in a wide variety of shapes, sizes, and filling materials. They can be mounted in aluminum holders, shaped according to your needs, with decorative or protective finishes for environments such as architecture, aeronautics, or maritime.

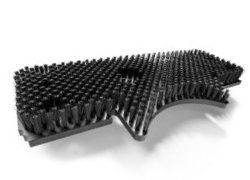

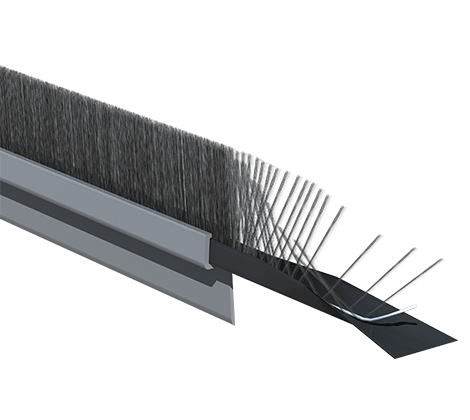

Principle of strip brush construction

The strip brush is a technical brush consisting of a U-shaped metal profile (usually made of electro-galvanized steel, stainless steel, brass, or aluminum), into which a retaining wire is inserted. The filling material is fixed between these two elements, and the entire assembly is crimped to ensure mechanical stability.

To facilitate installation, the strip brush is inserted into a holder or rail. In certain applications, the filling can be replaced or combined with materials such as rubber, neoprene, EPDM, or PVC.

Two essential dimensions

Two measurements are essential to define a strip brush:

- HT (Total Height): complete height of the brush, with or without support.

- S (Fiber Length): visible length of the filling material, which can exceed one meter.

These dimensions are defined on request and adapted to your equipment. At KOTI-TRIBOLLET, we have specialized for many years in the manufacture of strip brushes, produced in our own factory with recognized expertise. This allows us to guarantee consistent quality and tailor-made solutions for every application.

Cost-effective and long-lasting brush solutions | INDUSTRIAL BRUSH

Durability and customization

UV Protection: Technical brushes used outdoors can be exposed to UV rays. To prevent the degradation of synthetic fibers, we offer anti-UV treatments suitable for outdoor environments.

Custom development: At KOTI Tribollet, we regularly develop new configurations of technical brushes, including strip brushes specifically designed for machines or industrial processes. Our technical team supports you in defining the solution best suited to your needs.

Fast, efficient and flexible | INDUSTRIAL BRUSH

Filling materials for technical brushes

Le choix du matériau de remplissage est crucial pour l’efficacité de la brosse technique. Nous proposons une large gamme de fibres :

- Synthetic fibres: Nylon (6 / 6.6 / 6.10 / 6.12), Rilsan, polypropylene, polyester, polyethylene, abrasive nylon.

- Metal wires: High-strength steel, brass-coated steel, stainless steel, hardened steel, brass, bronze.

- Natural fibres: Horsehair, goat hair, pig bristles, goose and ostrich feathers; tampico (antistatic).

- Special fibres: Wytex, Pekalon, fiberglass, FRH, carbon fibre.

| Synthetic fibers | |

| Fibers | Application and characteristics |

| Nylon 6.6 | This quality is mainly used for industrial applications, offering excellent resistance to heat and wear. |

| Nylon 6.12 | Does not retain moisture, better resilience than nylon 6.6. |

| Rilsan | Does not retain moisture, excellent abrasion resistance. |

| Polypropylene (PP) | Does not retain moisture, resistant to acids, lower wear resistance compared to nylon 6.6 and 6.12. |

| Polyester (PBT) | Excellent heat resistance, good wear resistance, does not retain moisture, food-grade certified. |

| Nylon abrasive | For delicate burr removal, polishing, and satin finishing. |

| Polyethylene | Good chemical resistance with higher wet-state rigidity than nylon. |

| Metal wires | |

| Fibers | Application and characteristics |

| Steel | For carbon removal and deburring, very aggressive fibres. |

| Brass |

Polishing, satin finishing, offers very good antistatic electrical conductivity (slightly lower than that of bronze). |

| Stainless steel | Polishing, satin finish, offers very good antistatic electrical conductivity, suitable for humid environments. |

| Brass-plated steel | High tensile strength, long service life, deburring. |

| Twisted brass-coated steel | Twisted with reduced wire projection, long service life, deburring. |

| Phosphor bronze | Good conductivity for wood and metal surface treatment and for spark-free machining. |

| Natural fibers | |

| Fibers | Application and characteristics |

| Horsehair | Flexible fiber for light brushing (for example, for cleaning plastic strips). |

| Goat hair | Extremely soft fiber for delicate work. |

| Pig bristle | Harder than horsehair. |

| Goose feather | Patina of wooden furniture after polishing. |

| Ostrich feather | Very soft material, main application: dusting and polishing car bodies. |

| Tampico | Harder than pig bristle, for polishing metal with the addition of a polishing compound. |

| Special fibers | |

| Fibers | Application and characteristics |

| WYTEX conductive nylon | Synthetic fiber, very good electrical conductivity. |

| Nylon HT | Heat resistance up to 150°C |

| Pekalon | Synthetic fiber, good heat resistance up to 180–200°C. |

| PEEK | Synthetic fiber, good heat resistance up to 250°C. |

| Glass fiber | Very good heat resistance, high elasticity, good resilience (also used in the cardboard industry). |

| Carbon | Very high conductivity, very fragile material. |

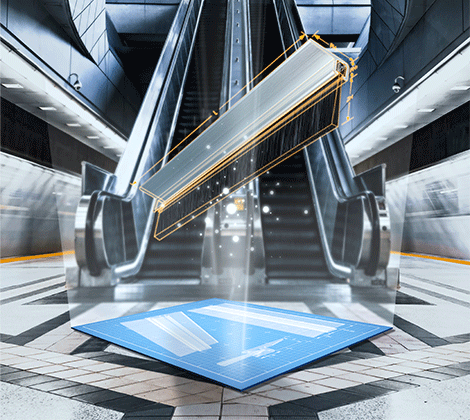

| FRH | Self-extinguishing nylon fiber, no emission of toxic gases when exposed to flames, used in areas where safety is a top priority (public transport). |

Technical brushes

Brushes for all industries

KOTI-TRIBOLLET develops and manufactures brushing solutions for all industrial sectors. From experience, we know that each market has its own specific needs, and our goal is to ensure that our brushes deliver added value to our customers. From our range of standard brushes to our custom solutions designed especially for you, we make sure you get the right brush for your requirements.

DISCOVER OUR SOLUTIONS

Wondering what our brushes can do for you? Our specialist advisors will be happy to help.